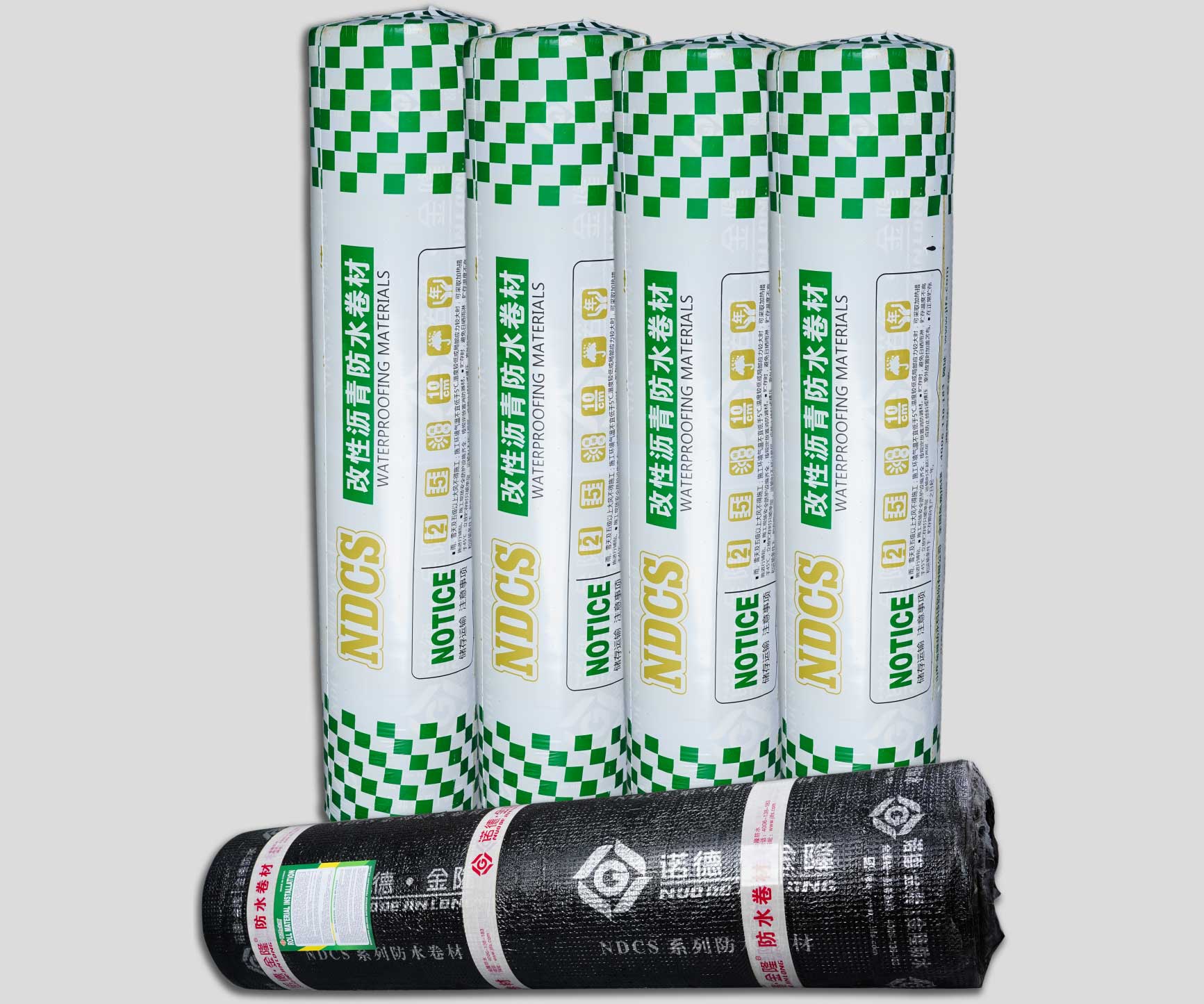

SBS/APP Modified Bitumen Waterproof Membrane

SBS modified bitumen waterproof membranes are made in a multi-layer design, surface coated with polyethylene (PE), film sand. Mineral granule or colorful sand, and have a high

Product Description:

SBS modified bitumen waterproof membranes are made in a multi-layer design, surface coated with polyethylene (PE), film sand. Mineral granule or colorful sand, and have a high level of flexibility along with a high strength. SBS modified bitumen waterproof membrane is highly resistant to the various weather conditions and are resistant to ageing and heat.

App plastic body modified asphalt waterproof rolling material is APP or APAO, APO modified asphalt as dip coating material, with high quality polyester felt, glass fiber felt as Tai Chi, a fine sand, mineral plum material, PE film as cover free material, the adoption of advanced process refined plastic body modified asphalt waterproof rolling material.

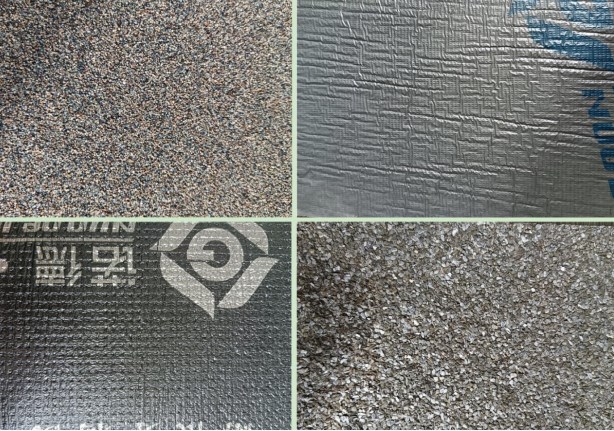

Product Details Pic:

Product Spec:

Product Name |

SBS APP Modified Asphalt Waterproofing Membrane |

Thickness(mm) |

3mm, 4mm, 4.5mm, 5.0mm,or customized |

Width (m) |

1m |

Length (m) |

7.5m,10m |

Surface |

PE film, Aluminum film, Sands, Mineral granules |

Application Method |

Torch applied |

Product Feature:

Technical Data

SBS Technical Data |

||||||

Item |

I |

II |

||||

PY |

G |

PY |

G |

PYG |

||

tensile property |

°C |

90 |

105 |

|||

10 |

||||||

testing phenomenon |

no flow, dripping |

|||||

low temperature flexibility |

-7 |

-15 |

||||

maximum peak pull |

500 |

350 |

800 |

500 |

900 |

|

maximum peak time elongation |

30 |

40 |

||||

oil leaking |

pieces |

2 |

||||

APP Technical Data |

|||||||||

Item |

I |

II |

|||||||

PY |

G |

PY |

G |

PYG |

|||||

tensile property |

°C |

110 |

130 |

||||||

10 |

|||||||||

testing phenomenon |

no flow, dripping |

||||||||

low temperature flexibility |

-7 |

-15 |

|||||||

maximum peak pull |

500 |

350 |

800 |

500 |

900 |

||||

maximum peak time elongation |

25 |

40 |

|||||||

oil leaking |

pieces |

2 |

|||||||

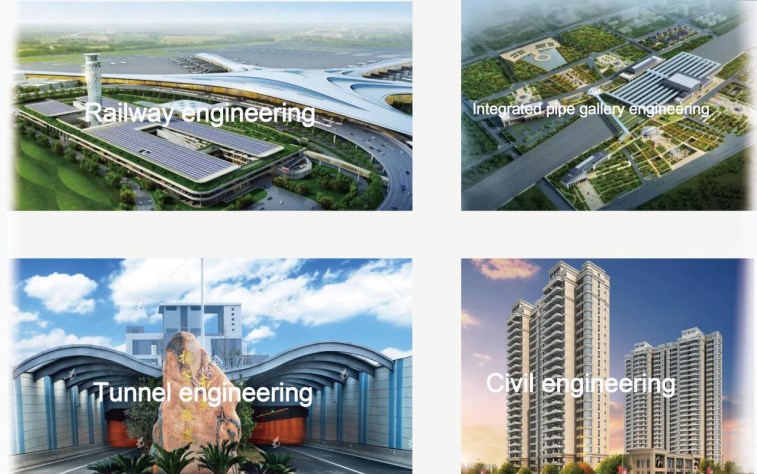

Product Application: